NEWS

Automatic vermicelli pasta macaroni making machine

Saibainuo Machinery

Food Machinery--High quality.Factory price!

Email: extruder@foodmachine.cc

website: www.china-food-extruder.com

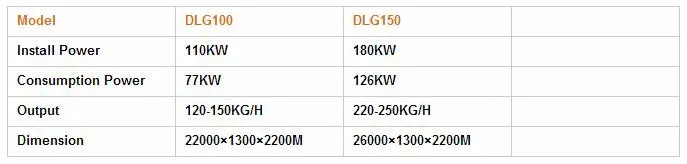

Phone(Whatsapp): +0086 18668988231

For more information of macaroni pasta machine please click here:macaroni pasta machine

Introduction of Full-automatic Italian Pasta product line/macaroni making machine

/pasta processing machine:

1.Macaroni pasta is produced by single-screw extruder through extruding cooking;

the pellet can be different shapes like shell, spiral, square tube, circle tube,

and so on. After drying, the pellet needs frying to get expanded.

2.Raw material: adopts potato starch, corn starch, cassava starch, wheat flour,

corn flour etc as raw materials. This line can be used to produce different shapes

of pellets by adjusting the moulds from extruderAll the machines are made by

stainless steel, this line is with reasonable design and with high automation; the

screws are made by alloy steel, with building block system structure and

self-cleaning function.

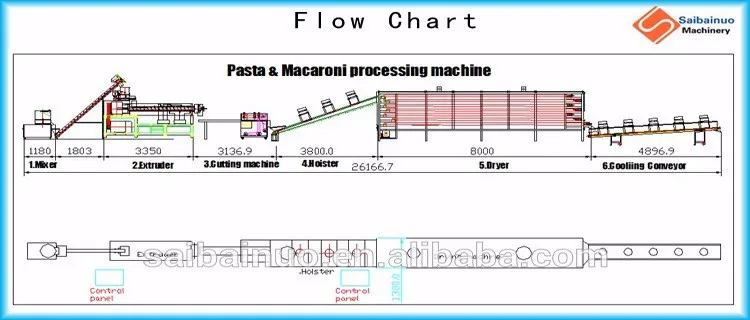

3. Main Flow chart for pasta processing machine,macaroni pasta maker machine:Raw

material mixing-----Extrusion-----Cutting-----Drying------Cooling-----Packing.

4.Voltage: In China Three phases : 380V/50Hz, Single phase: 220V/50Hz,we can make

it according to customers’ Local voltage according to different countries.

5. Machines Materials: All the machines are made by stainless steel

6.Specification of the pasta processing machine,macaroni pasta maker machine

The flow chart:

Saibainuo Machinery

Email: extruder@foodmachine.cc

website: www.china-food-extruder.com

Phone(Whatsapp): +0086 18668988231

Characteristics:

1).Various models to meet different output capacity requirements.

2).Flexible configurations to meet different produce, budget and workshop layout

requirement.

3).Vast raw material range to produce different final products by only one

production line.

4).Different shapes and appearances of final products can be made by changing

different modules in extruder.

5).High automation and accurate control system to save labor cost and improve the

quality of final products.

6).Independent temperature control system is able to realize zone temperature

control, electronic induction, accurate & visual digital display.

7).Feeding system without material returning.It is unnecessary to clean barrel and

screw in case of restarting or material replacement.

8).Screw adopts high-performance nitride alloy steel with strong wear-resistance

and longer service life.

9).Food-grade stainless steel. Neatness and easy clean.

Saibainuo Machinery

Email: extruder@foodmachine.cc

website: www.china-food-extruder.com

Phone(Whatsapp): +0086 18668988231

Finished products andready for shipment: