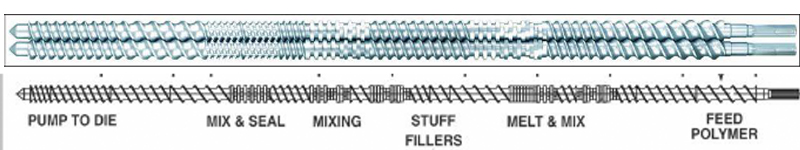

Specification of Twin Screw

Figure 1: Co-rotating intermeshing twin screw extruder screw set

Process control parameters include screw speed (rpm), feed rate, barrel/die temperatures, and vacuum level. Typical

readouts include melt pressure, melt temperature, motor amperage, and in-line optical sensors. Depending on how the TSE

is configured and operated, residence times can be as short as 5 seconds, as long as 10 minutes, and are typically in the 20

second to 2 minute range.

Starve feeding refers to the extruder being fed at a rate less than the forwarding efficiency of the screws. The independence

of feed rate from screws rpm facilitates control of surface area generation, residence time, and mixing (to eliminate gradients);

and is what makes the TSE an effective tool for stripping volatiles from polymer melts.

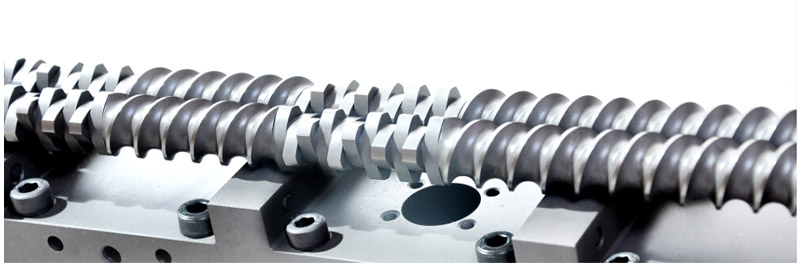

Barrels segments include the provision for venting. The pressure gradient in the twin screw extruder is controlled and, to a

significant degree, determined by the selection of screws. Flighted elements are strategically placed so that the screw channels

are not filled, which results in a zero pressure underneath vent sections that prevents vent flooding, and also allows downstream

feeding of fillers/fibers+.

- 上一篇:已经没有了

- 下一篇:Dellivery pet food machine to Indonesia